FABRIC GRAVITY FILTRATION

Baron Blakeslee Fabric Gravity Filtration systems are engineered to meet the diverse needs of multiple industries and applications, providing efficient filtration solutions for a wide range of fluids. These systems are ideal for use in:

Industrial Wastewater:

Baron Blakeslee Fabric Gravity Filtration systems are adept at handling industrial wastewater, effectively removing contaminants and impurities to ensure compliance with regulatory standards. Whether it's removing suspended solids, oils, or other pollutants, our filtration systems deliver reliable performance, helping industries minimize their environmental footprint and adhere to wastewater treatment regulations.

Machine Tool Coolant:

Our Fabric Gravity Filtration systems are ideal for maintaining the cleanliness and effectiveness of machine tool coolant systems. By efficiently removing particulates, tramp oils, and other contaminants from coolant fluids, our filtration solutions help extend tool life, improve machining accuracy, and reduce maintenance costs, ensuring optimal performance of machine tools and enhancing overall productivity.

Parts Washers:

Baron Blakeslee Fabric Gravity Filtration systems offer efficient filtration solutions for parts washers, ensuring thorough cleaning and removal of contaminants from components. Whether it's in automotive, aerospace, or manufacturing applications, our filtration systems help maintain the cleanliness and integrity of parts washers, ensuring high-quality finished products and minimizing rework or rejection rates.

Phosphating:

In phosphating processes, our Fabric Gravity Filtration systems play a crucial role in maintaining bath cleanliness and prolonging chemical solution life. By effectively removing solids and contaminants from phosphating solutions, our filtration systems help optimize coating quality, reduce chemical consumption, and minimize downtime associated with bath maintenance, ensuring consistent and reliable performance in metal surface treatment processes.

Process or Cooling Water:

Baron Blakeslee Fabric Gravity Filtration systems are highly effective in treating process or cooling water, removing suspended solids and impurities to ensure optimal system performance and longevity. Whether it's in industrial cooling towers, HVAC systems, or manufacturing processes, our filtration solutions help prevent equipment fouling, corrosion, and scale buildup, improving energy efficiency and reducing maintenance requirements.

Treated Plating Waste:

Our Fabric Gravity Filtration systems are well-suited for treating treated plating waste, efficiently removing residual contaminants and impurities to meet discharge standards and environmental regulations. By effectively separating solids from plating waste solutions, our filtration solutions help industries minimize environmental impact, reduce wastewater treatment costs, and ensure compliance with regulatory requirements.

Water Wall Spray Booths:

Baron Blakeslee Fabric Gravity Filtration systems provide reliable filtration solutions for water wall spray booths, ensuring efficient removal of overspray and contaminants from spray booth water systems. By effectively capturing and removing paint particles and other pollutants, our filtration systems help maintain clean and compliant water systems, ensuring optimal performance and longevity of spray booth equipment.

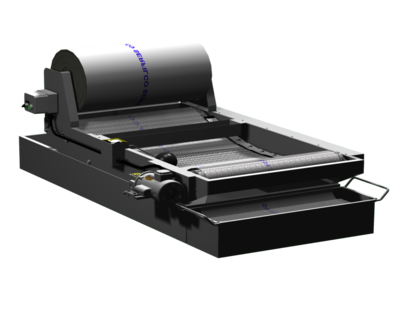

Robust Construction and Easy Maintenance

Baron Blakeslee Fabric Gravity Filtration systems feature robust construction and are designed for ease of maintenance, ensuring long-term reliability and hassle-free operation. With a choice of painted mild steel or 316L stainless steel construction, these systems are built to withstand harsh industrial environments while providing efficient filtration performance.

Key Features of Fabric Gravity Filtration Systems

- Choice of painted mild steel or 316L stainless steel construction

- Filter surface areas ranging from 1.5 square foot to 113 square foot

- Flow ratings ranging from 2 to 646 gallons per minute

- Low operating cost

- Unattended operation

Efficient and Automatic Filtration Process

Baron Blakeslee Fabric Gravity Filtration systems offer a completely automatic filtration process that responds to wide variations in flow rate and solids concentration. The contaminated solution is transferred to the diffuser tray by a pump, which distributes the flow evenly across the full width of the filter bed. Gravity flow through the media initiates particle separation, with filtered solution draining to the clean reservoir below the conveyor frame.

Gentle Solids Accumulation and Settling

The gravity flow mechanism allows gentle accumulation and settling of solids on the filter fabric, ensuring efficient filtration without compromising the integrity of the process. The concave configuration of the media bed accommodates the flow rate and maximizes solids loading on the fabric, optimizing filtration performance, and prolonging fabric lifespan.

Automatic Fabric Advancement and Maintenance

As the media becomes laden with solids, the solution level gradually rises until the float switch activates the conveyor drive motor. Consumed fabric is advanced to the sludge box while fresh media is simultaneously indexed to the solution flow, ensuring continuous and uninterrupted filtration operation. The system includes essential components such as the solution reservoir, sludge box, float switch level control for belt motor, SS 316 conveyor belt, and magnetic motor starter with HAND-OFF-AUTO selector switch, providing comprehensive functionality and ease of operation.

Trust Baron Blakeslee Fabric Gravity Filtration systems for efficient and reliable filtration solutions tailored to your specific application needs. Contact us today to learn more about our versatile filtration systems and how they can optimize your processes.