Corrosion is a common yet harmful issue that affects Printed Circuit Boards (PCBs), leading to decreased performance or complete failure. Understanding how to protect PCB from corrosion can make all the difference in the longevity and efficiency of your electronics.

In this article, we will explore effective methods for preventing corrosion, signs to watch for, and how to maintain and clean your PCBs to keep them running smoothly.

Understanding PCB Corrosion

PCBs are the backbone of most electronic devices, connecting various components and allowing them to function properly. Corrosion occurs when metals on the PCB react with substances like water, oxygen, and salts, forming compounds that compromise the integrity of the board.

Factors like humidity, chemical exposure, and temperature fluctuations accelerate the corrosion process. Over time, the protective coating on the PCB may wear down, exposing the metal beneath. This increases the likelihood of corrosion setting in, which can disrupt electrical connections, causing malfunction or complete failure.

Understanding these factors is the first step in learning how to protect PCB from corrosion. Implementing preventative measures and regular maintenance will help prolong the life of your PCBs and keep them performing optimally.

Signs of Corrosion on PCBs

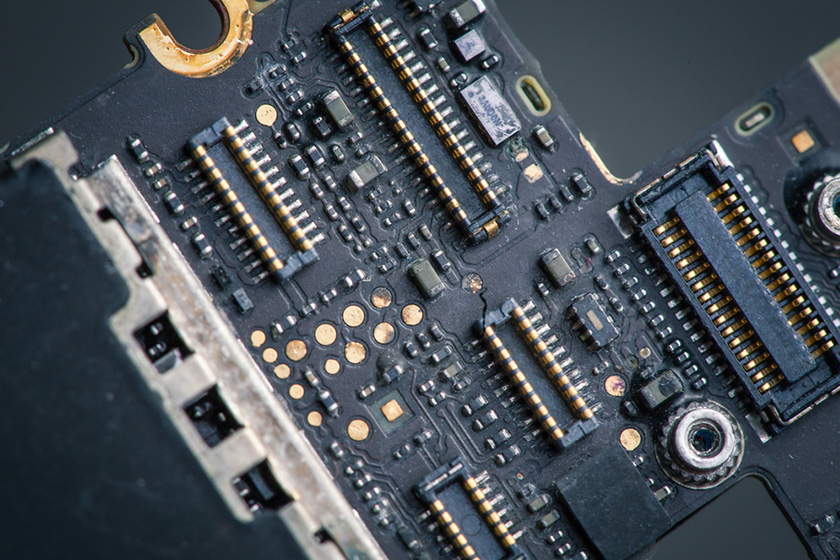

Some common signs of corrosion on circuit boards include discoloration, visible oxidation, and physical damage to the board’s surface. These issues often stem from the reaction of moisture or chemicals with the metal components of the PCB.

In some cases, corrosion can lead to the failure of individual components or disrupt the overall functioning of the circuit. For example, corrosion can cause electrical shorts or loss of signal integrity. Identifying these signs early allows for prompt action, which can prevent extensive damage to the PCB.

If corrosion is left unchecked, it can worsen over time, leading to higher repair or replacement costs.

Best Practices for Preventing PCB Corrosion

Protecting your PCBs from corrosion starts with a combination of preventive measures and regular maintenance. Here are the best practices for ensuring that your PCBs remain free from corrosion.

Cleaning

PCBs used in Defense, High Reliability or Medical applications are generally cleaned during the manufacturing operation to remove solder flux or paste that could potentially become corrosive if left on the PCB. Defluxing of PCBs immediately after the soldering or reflow process has long been used in critical industries to prevent corrosion from the start. Cleaning is also essential before the application of a conformal coating. Cleaning is often used in rework applications as well. Baron Blakeslee offers a wide range of PCB cleaning equipment such as vapor degreasers, aqueous cleaning equipment, and systems designed for use with isopropyl alcohol.

Environmental Control

One of the most effective ways to protect your PCB is by controlling the environment in which it operates. Moisture is one of the leading causes of corrosion, so keeping your PCBs in dry, controlled environments is an important first step. This can be achieved by using dehumidifiers in areas with high humidity levels or storing electronic devices in airtight enclosures.

Temperature also plays a significant role in PCB corrosion. Fluctuating temperatures can cause condensation inside devices, creating an ideal environment for corrosion. Keeping electronics in stable temperature ranges helps minimize the risk.

Using Protective Coatings

A reliable way to shield PCBs from environmental damage is by applying conformal coatings. These coatings are thin layers of protective material applied to the PCB to safeguard the components against moisture, dust, and chemicals. There are several types of coatings available, including acrylic, silicone, and epoxy, each providing different levels of protection.

By applying a protective coating, you create a barrier between the PCB and potentially harmful environmental elements, effectively reducing the risk of corrosion. This is a straightforward, yet highly effective, method for extending the life of your PCBs.

Regular Cleaning and Inspection

Keeping PCBs clean and regularly inspecting them for signs of corrosion are important steps in their maintenance. Dust, dirt, and debris can accumulate on the board over time, potentially trapping moisture or chemicals against the surface and increasing the likelihood of corrosion. Regular inspections allow for early detection of corrosion, enabling corrective action to be taken before the damage becomes significant.

At Baron Blakeslee, we understand the importance of preserving the integrity of your PCBs. Using our specialized electronics cleaning equipment, you can clean your circuit boards effectively without risking damage to sensitive components. Trust us to deliver solutions that maintain the highest standards of quality.

Proper Storage and Handling

When not in use, PCBs should be stored in environments that minimize exposure to moisture, dust, and chemicals. Using sealed bags with moisture-absorbing materials like silica gel or desiccants helps keep the boards dry.

Handling the PCBs carefully is also a great way to avoid physical damage that could expose the components to corrosion. Always wear anti-static gloves when working with PCBs to prevent oils and residues from your hands from coming into contact with the board.

How to Clean Corrosion Off a Circuit Board

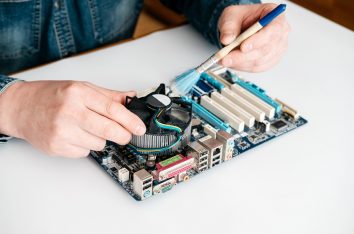

If corrosion has already formed on your PCB, it is important to clean it off as soon as possible to prevent further damage. Always use gentle, non-abrasive cleaning methods to avoid damaging the delicate components.

Start by using isopropyl alcohol or a dedicated electronics cleaner. Gently scrub the affected areas with a soft brush to remove corrosion. If the corrosion is caused by water exposure, use a soft cloth or brush to clean the water corrosion off the circuit board, ensuring you avoid applying excessive force, which could dislodge components.

Vapor degreasing is also an effective method used to clean delicate electronic components like PCBs. This process involves the use of a solvent that evaporates to create a vapor, which is then used to remove oils, dirt, and solder flux or paste from the surface of the board.

It is particularly advantageous because it doesn't require direct contact with the components, reducing the risk of physical damage. The vapor is capable of reaching even the most intricate areas of the circuit board without causing harm.

Long-Term Protection Tips for PCBs

In addition to preventing corrosion, long-term protection requires consistent effort. Consider using moisture-absorbing materials, such as silica gel, in any storage or operational areas where your PCBs are present. These materials help to maintain a dry environment and reduce the likelihood of corrosion setting in.

Additionally, regular cleaning and inspections should be part of your ongoing PCB maintenance routine. Even with protective coatings and proper storage, dust and moisture can still find their way onto the board. Keeping your PCBs clean and free from contaminants is a proactive step in preventing corrosion from affecting their performance.

Keeping Your PCBs Safe and Functioning

Protecting your PCBs from corrosion supports the longevity and reliability of your electronic devices. By implementing preventive measures such as environmental control, protective coatings, and regular cleaning, you can significantly reduce the risk of corrosion. Whether you need to learn how to clean water corrosion on a circuit board or are looking for long-term solutions to prevent future damage, taking proactive steps is essential.

We offer top-of-the-line electronics cleaning equipment at Baron Blakeslee, designed to keep your circuit boards in excellent condition. Contact us today for more information on how our solutions can help you maintain the integrity of your electronic components.