Industrial dryers are used in manufacturing, processing, and research. They are designed to remove moisture from materials, improving quality, preserving products, and preparing materials for further processing.

In this article, we’ll explore the different types of industrial dryers and how they work, highlighting their applications across various industries. Let’s break down each dryer type and its applications to provide a comprehensive understanding of industrial drying methods.

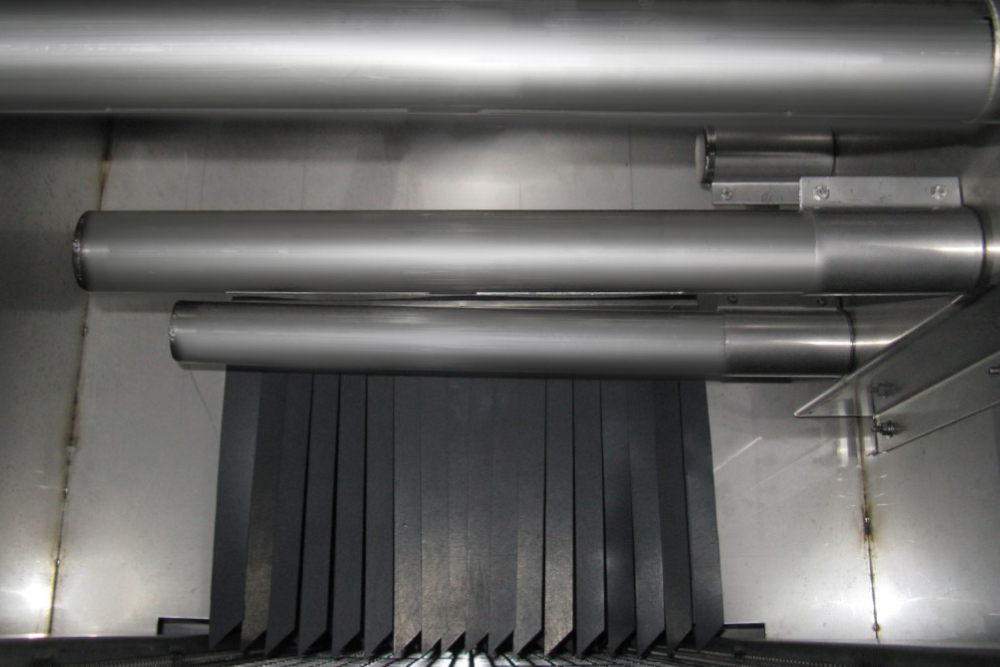

Hot Air Parts Dryers

Hot air parts dryers are one of the most widely used types of industrial dryers. These dryers use heated air to remove moisture from parts, making them an efficient choice for a wide range of industries.

At Baron Blakeslee, we offer a variety of hot air parts dryers in both batch and conveyorized forms. These dryers can be heated in different ways, including electric, gas, or steam, depending on the application and energy preferences. This versatility allows manufacturers to choose the heating method that best fits their needs and energy budgets.

How hot does an industrial dryer get? Hot air parts dryers can typically reach temperatures ranging from 120°F to 400°F (49°C to 204°C), depending on the material being dried and the specific requirements of the application. The precise temperature is adjustable and should align with the needs of different parts and processes.

One of the primary advantages of hot air parts dryers is their ability to accommodate a variety of part sizes and shapes. We offer custom hot air parts dryers that are tailored to suit any application, whether it involves small components or large batches of parts. These dryers are also available in designs that integrate seamlessly with existing process lines, improving production efficiency.

In addition to standard designs, we also offer automation for industrial dryers, which can help streamline processes and reduce labor costs. Automation allows for unattended processing, adding repeatability and consistency to drying cycles. This feature is particularly beneficial for industries looking to improve productivity while minimizing human error.

Applications of hot air parts dryers are widespread, including drying metal parts, electronic components, and plastic materials. These dryers also play a key role in electronics manufacturing, where they remove moisture from circuit boards or sensitive components before further assembly.

Drum Dryers

Drum dryers are another popular type of industrial dryer, especially in industries that require drying of large quantities of materials, such as foods, chemicals, and pharmaceuticals. These dryers work by rotating a heated drum, which dries the material that is applied in a thin film on the drum's surface. The material is then scraped off the drum once it is dried, leaving a consistent, even layer of dried product.

In food processing, drum dryers are frequently used for drying liquid or semi-liquid materials, such as milk or fruit purees. These materials are spread onto the rotating drum and dried by heat.

Once dried, the product can be ground or further processed. This drying method is particularly effective for products that need to retain their flavor, texture, and nutritional value, such as instant foods, fruit powders, and baby food ingredients.

In the chemical and pharmaceutical industries, drum dryers are often used for drying slurries, pastes, and powders. These dryers are efficient for materials that need consistent drying across large surface areas, making them suitable for bulk drying applications.

One of the main benefits of drum dryers is their ability to handle materials that may not flow easily or that require gentle drying. The nature of drum dryers makes them suitable for large-scale production processes, offering high drying efficiency and reducing the overall drying time.

The choice of drum dryers for industrial applications depends on several factors, such as material type, moisture content, and drying time. For example, thicker pastes or slurries may require more time to dry, while thin layers of liquid materials will dry faster, making it important to adjust the system’s settings accordingly.

Vacuum Dryers

Vacuum dryers are widely used for drying heat-sensitive materials in a controlled environment. These dryers work by creating a vacuum that reduces the pressure around the material, lowering the boiling point of water and allowing moisture to evaporate at lower temperatures. This makes vacuum dryers an ideal choice for materials that may degrade or lose their properties at higher temperatures.

In industries like pharmaceuticals and food processing, vacuum dryers are useful for preserving the integrity of sensitive materials. For example, in the pharmaceutical industry, they are used to remove solvents from active pharmaceutical ingredients (APIs) after synthesis, without compromising the quality of the final product. By operating at lower temperatures, these dryers prevent the material from overheating or losing potency.

Food processing also benefits from vacuum dryers, particularly in the preservation of products that need to maintain their natural color, flavor, and texture. Freeze-drying is, in fact, a type of vacuum drying used to preserve fruits, vegetables, and meals, as it removes moisture while keeping the product intact. Vacuum dryers are also ideal for drying herbs, spices, and other delicate products that would otherwise degrade with traditional drying methods.

In addition to their application in pharmaceuticals and food processing, vacuum dryers are used in the chemical industry to dry solvents, coatings, and specialty chemicals. They are also used in electronics manufacturing to dry components like circuit boards, ensuring that no moisture remains before further assembly processes.

Freeze Dryers

Freeze dryers, also known as lyophilizers, are a specialized type of industrial dryer used to preserve materials by removing moisture under low temperature and pressure. The process of freeze drying involves freezing the material, followed by sublimation, where ice is directly converted into vapor without passing through the liquid phase. This method is highly effective for preserving the structure, flavor, and nutritional content of materials while ensuring minimal degradation during drying.

In the food industry, freeze dryers are commonly used to produce freeze-dried fruits, vegetables, and prepared meals. The process allows for long-term storage without refrigeration while maintaining the original characteristics of the food.

Freeze-dried foods are lightweight and retain their flavor and nutrients, making them ideal for the outdoor and emergency food sectors. Such meals are popular in camping, hiking, and military rations.

Freeze dryers are also widely used in the pharmaceutical and biotechnology industries to preserve sensitive biological materials, such as vaccines, proteins, enzymes, and cell cultures. These products often require preservation in their original form to maintain their efficacy.

This drying process prevents the breakdown of sensitive compounds and ensures that they retain their potency when reconstituted. In the laboratory, freeze-drying is a critical process for preserving samples for long-term storage and transport.

Because the drying process occurs at low temperatures, freeze-drying is ideal for heat-sensitive materials that might degrade or lose their effectiveness with traditional drying methods. Though freeze dryers tend to be more expensive than other drying methods, their ability to preserve material quality makes them invaluable in industries where quality is paramount.

Fluidized Bed Dryers

Fluidized bed dryers are used primarily for drying fine powders and granular materials. This type of dryer works by forcing heated air through a material bed, causing the material to become suspended and behave like a fluid. The process promotes even heat distribution, ensuring that the moisture is removed uniformly across the material.

Fluidized bed dryers are particularly well-suited for industries such as food processing, pharmaceuticals, and chemicals, where the material being dried is typically in the form of powders, granules, or pellets. For example, in food processing, fluidized bed dryers are used for drying grains, spices, and sugar, as well as for coating particles with powdered ingredients. These dryers are also effective for drying pharmaceutical powders, granules, and excipients that require precise moisture content control.

One of the main advantages of these dryers is their ability to provide uniform drying. As the material is suspended in the air, each particle is exposed to heat evenly, which results in a consistent drying process. This uniformity is particularly important when drying materials that need to meet strict quality standards, such as in the production of pharmaceuticals and food products.

In addition to providing even drying, fluidized bed dryers are also energy-efficient. The fluidization process increases the surface area of the material, allowing for faster drying times. The high heat transfer efficiency means that the drying process can be completed in less time compared to other drying methods, reducing energy consumption and improving overall efficiency.

Fluidized bed dryers are highly versatile and can be adapted for various drying needs. They can be used to dry a wide range of materials and are an excellent choice for industries with diverse drying requirements.

Rotary Dryers

Rotary dryers are one of the most commonly used types of industrial dryers, particularly in industries dealing with bulk materials such as chemicals, minerals, and aggregates. These dryers consist of a large, rotating drum where materials are tumbled as hot air is passed through them. The rotation of the drum helps expose the material to the heated air, facilitating the removal of moisture.

In industries like mining, construction, and chemical processing, rotary dryers are used to dry a variety of materials, including ores, sand, and fertilizers. For example, in the mining industry, rotary dryers are commonly used to dry minerals and aggregates that have been extracted from the earth. In chemical processing, rotary dryers are used to dry materials like pigments, plastics, and powders.

One of the key advantages of rotary dryers is their ability to handle large volumes of material. They are particularly effective for drying bulk solids that are difficult to handle with other dryer types. The continuous operation of a rotary dryer means that large quantities of material can be processed efficiently, making it a valuable asset in large-scale manufacturing operations.

Rotary dryers are also versatile in terms of the type of material they can dry. They are effective for drying both fine and coarse materials, and the drying conditions can be adjusted to suit the specific needs of the material being processed.

Despite their efficiency, rotary dryers can be more energy-intensive than other dryer types, particularly for materials that require a long drying time. However, their ability to handle large volumes of material and their flexibility in drying different types of substances make them a popular choice for industries that need high-capacity drying solutions.

How Long Do Industrial Dryers Take?

The drying time for industrial dryers can vary significantly based on several factors, including the type of material being dried, the specific dryer being used, and the moisture content of the material. Generally, the drying process can take anywhere from a few minutes to several hours.

Finding the Right Industrial Dryer for Your Application

Different types of industrial dryers each offer unique advantages based on the specific needs of the material being dried and the industry in question. We design custom industrial dryers to meet the unique needs of your business. Our team can provide solutions that integrate seamlessly into your existing process lines, improving efficiency and productivity.

Request information to learn more about how our industrial dryers can help streamline your production processes and enhance your product quality.