Aluminum sheet metal is used in many industries, creating parts and products that are both lightweight and durable. Aluminum sheet metal fabrication involves using various techniques to cut, bend, and shape aluminum into desired forms for industrial and commercial applications.

In this guide, we’ll explore the aluminum fabrication process, discuss its various applications, and provide insights into how the cost of aluminum sheet metal can affect production.

What Is Aluminum Fabrication?

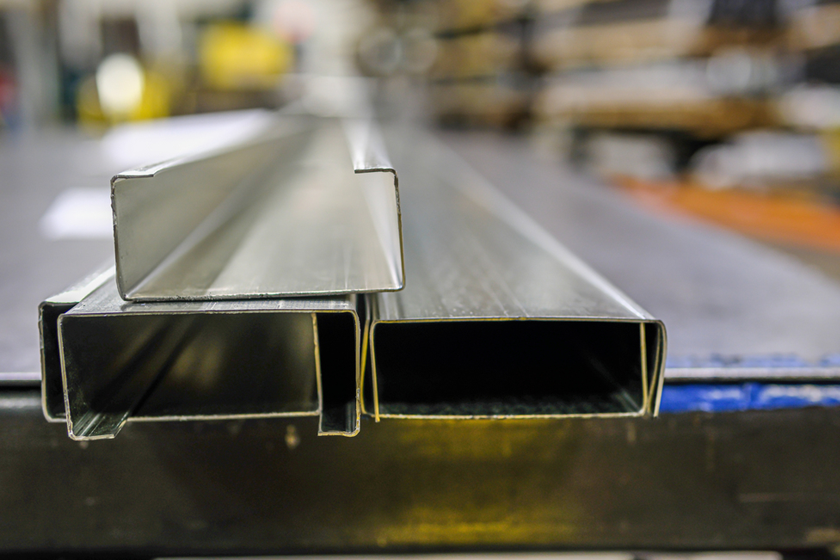

This is the process of transforming aluminum materials into finished parts, components, or products through various techniques such as cutting, bending, welding, and finishing. Aluminum is chosen for its exceptional properties, including its lightweight nature, corrosion resistance, and high strength-to-weight ratio. These features make it a popular material for industries that require durable yet lightweight components.

Aluminum fabrication is an important process in manufacturing, used to produce a wide range of products, from structural frames to intricate electronic housings. The fabrication process typically starts with raw aluminum sheets or coils, which are then cut and shaped according to precise specifications.

Skilled fabricators utilize various tools and technologies to manipulate the material, ensuring that it meets the quality and performance standards required by the end user.

The process improves product quality by ensuring that the final product is durable, lightweight, and corrosion-resistant. Surface treatments like anodizing or powder coating enhance the appearance of aluminum products. Additionally, they provide an added layer of protection against environmental factors.

The Process of Aluminum Sheet Metal Fabrication

The process of aluminum sheet metal fabrication involves several steps. While the exact steps can vary depending on the product and industry, the basic process usually includes designing, cutting, bending, welding, and finishing.

In the design phase, CAD (Computer-Aided Design) software is often used to create detailed blueprints of the part or product to be fabricated. Once the design is finalized, the aluminum sheet is cut to the desired size using tools like laser cutters, water jets, or shears. The choice of cutting method depends on the thickness of the aluminum and the precision required.

After cutting, the metal is often bent into the desired shape. This can be done using a press brake or other bending tools that allow the metal to be precisely formed. For more complex shapes, additional forming techniques may be used.

Next, the aluminum may need to be welded or joined together, especially if it’s part of a larger assembly. Various welding techniques, such as MIG or TIG welding, are employed to ensure a strong, clean bond between the metal pieces. The process is carefully controlled to prevent defects that could affect the product’s integrity.

Finally, the aluminum part may undergo surface finishing to improve its appearance or to protect it from corrosion. This could involve anodizing, powder coating, or painting, each method providing a different level of protection and aesthetic appeal.

Applications of Aluminum Sheet Metal Fabrication

One of the most common applications is in the aerospace industry, where aluminum’s lightweight and high-strength properties make it ideal for creating parts like aircraft wings, fuselages, and engine components.

The automotive industry also relies on aluminum fabrication for car body panels, engine components, and wheels, benefiting from the material’s ability to reduce vehicle weight without compromising strength.

In the construction industry, aluminum fabrication is used to create building components such as roofing, siding, window frames, and structural supports. The material’s resistance to corrosion makes it ideal for outdoor applications exposed to the elements.

The electronics industry uses aluminum sheet metal for protective housings, heat sinks, and enclosures for various electronic devices. The non-corrosive nature of aluminum ensures that the internal components of these devices are well-protected from moisture and environmental damage.

Additionally, aluminum is used in furniture design, industrial machinery, and even packaging, where its durability and lightweight properties are highly valued. The versatility of aluminum sheet metal makes it indispensable across multiple sectors, ensuring that products meet performance standards while remaining cost-effective.

How Much Does Aluminum Sheet Metal Cost?

The cost of aluminum sheet metal depends on various factors, including the thickness, alloy, and finish of the metal. Typically, aluminum sheet metal is sold per square foot or per pound, with pricing varying based on market conditions and material specifications.

Alloys that contain higher levels of elements like magnesium or copper can be more expensive but may offer additional strength or corrosion resistance. The cost can also fluctuate based on the availability of aluminum in the global market and the specific industry’s demand.

Additionally, the complexity of the fabrication process plays a significant role in the final cost. For example, custom parts requiring intricate cuts, precise bending, or specialized finishing can increase the overall price. Bulk purchases or larger orders can often lead to a lower per-unit cost, as manufacturers can streamline production and reduce waste.

As aluminum is a highly recyclable material, the recycling process can influence its price as well. Recycled aluminum costs less to produce than virgin aluminum, and more companies are turning to recycled material as a way to reduce both costs and environmental impact.

Challenges in Aluminum Sheet Metal Fabrication

While aluminum sheet metal fabrication offers numerous benefits, there are challenges involved in the process. One of the main challenges is the material’s tendency to expand when heated, making it difficult to control during welding or forming processes.

This requires highly skilled technicians who are experienced in working with aluminum and can minimize distortion during fabrication.

Another challenge is the potential for surface imperfections, which can occur during cutting, bending, or welding. These imperfections may affect the aesthetics or performance of the product and may require additional finishing or quality control measures.

By combining cutting-edge technology with experienced craftsmanship, our team at Baron Blakeslee consistently overcomes these fabrication challenges. Our state-of-the-art facilities, coupled with our team of highly experienced technicians, ensure that every project is executed with unparalleled accuracy. We leverage the latest technology and advanced techniques to mitigate the challenges associated with aluminum fabrication.

Why Aluminum Sheet Metal Fabrication Matters

Aluminum sheet metal fabrication is an important process for industries that demand high-quality, lightweight, and durable materials. It is the perfect solution for producing parts that meet stringent performance standards while remaining cost-effective.

For reliable and high-quality industrial fabrication services, we are here for you. In addition to aluminum sheet metal fabrication, we offer a full range of fabrication solutions and manufacture a range of custom and standard industrial equipment. Reach out today to discuss your project.