The global manufacturing landscape has evolved into a complex network of specialized production partners, outsourced engineering teams, and multinational supply chains. In this ecosystem, choosing between contract manufacturing vs. third-party manufacturing can directly shape product quality, development control, timelines, and long-term scalability. For companies developing technical, engineered, or highly customized products, aligning with the right...

Category: Blog Archives

What Is The Best Industrial Parts Drying Method?

After any industrial cleaning, rinsing, or surface preparation process, the single factor that determines a component's fitness for the next stage is its dryness. Even microscopic traces of moisture can promote flash corrosion, compromise adhesion for subsequent coatings, and introduce minute residue that destabilizes sensitive assemblies. When parts exit the wash stage of a typical...

How Much Does Contract Manufacturing Cost?

When businesses look to scale production without investing in new facilities, they often turn to contract manufacturing. How much does contract manufacturing cost? The price can vary significantly depending on various factors, including the complexity of the product, order volume, materials, and more. Understanding these underlying pricing factors can help set realistic expectations and optimize...

How Industrial Dryers Improve Product Quality And Efficiency

In any production process, every process stage must be controlled to guarantee the quality of the final product. While attention often focuses on mixing, processing, or machining, a component's final state of dryness is often the most significant factor determining its fitness for the market. Moisture can compromise expensive components in the final moments of...

How Does An Air Dryer Work? Understanding The Process

In countless industrial and manufacturing settings, compressed air serves as an invaluable utility, driving tools, operating machinery, and even transporting materials. However, the air we compress contains water vapor, and once pressurized, that vapor becomes a highly concentrated source of moisture. Unchecked, this moisture can cause extensive damage and operational issues throughout an air system....

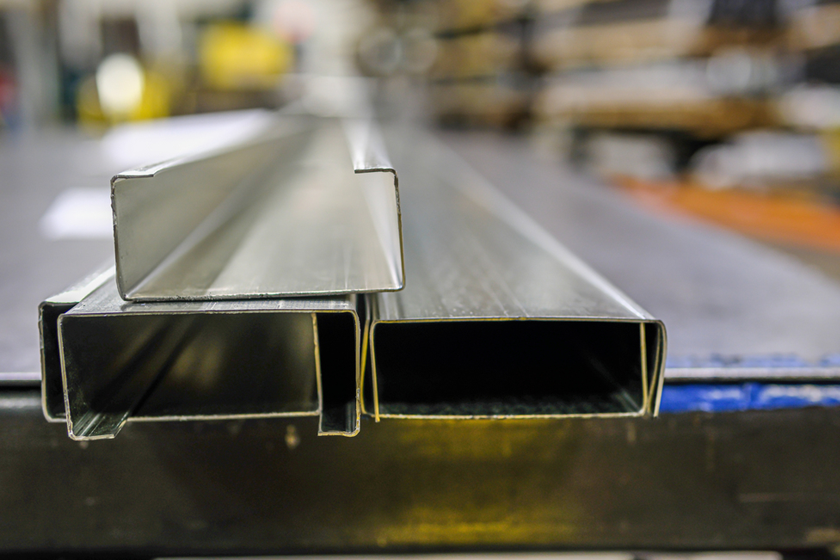

A Guide To Aluminum Sheet Metal Fabrication

Aluminum sheet metal is used in many industries, creating parts and products that are both lightweight and durable. Aluminum sheet metal fabrication involves using various techniques to cut, bend, and shape aluminum into desired forms for industrial and commercial applications. In this guide, we’ll explore the aluminum fabrication process, discuss its various applications, and provide...

Understanding The Procedure Of Pressure Testing A Heat Exchanger

Pressure testing a heat exchanger is a vital step in confirming its integrity and safe operation. In industrial and marine systems, improper functioning can lead to leaks, equipment damage, and operational inefficiencies. Through pressure testing a heat exchanger, technicians can identify weak spots, check for leaks, and validate the structural soundness of the equipment before...

Is 70% Isopropyl Alcohol Safe For Electronics?

Cleaning electronics often requires careful consideration of the materials, components, and exposure to liquids. Many users wonder, is 70% isopropyl alcohol safe for electronics? While 70% isopropyl alcohol can remove dust, oils, and grime from certain surfaces, the water content in this concentration introduces risks. About 30% of the solution is water, which can seep...

How To Check Heat Exchanger Performance

Checking the efficiency and operation of a heat exchanger is an important step for industrial, commercial, and process systems. Understanding how to check heat exchanger performance allows operators to identify issues before they become costly. Monitoring performance not only ensures energy use is optimized but also reduces the risk of damage to critical equipment. In...

Contract Manufacturing Vs. Outside Processing: Which Is The Better Option?

Choosing the right production strategy can influence efficiency, cost, and overall business growth. Many companies face the decision between contract manufacturing and outside processing. Understanding how contract manufacturing works helps clarify its role compared to traditional outsourcing. In this post, we explore the differences, benefits, and limitations of both approaches, offering insight for companies looking...