Anyone who has cleaned a carburetor the old-fashioned way knows the routine. Parts come apart piece by piece, solvents get sprayed or brushed on, and stubborn varnish still hides deep inside tiny passages. Ultrasonic cleaning gained traction for its faster cycles, reduced manual effort, and ability to reach areas brushes cannot reach. That promise raises...

Author: admin

Can Ultrasonic Cleaning Damage Rubber Components?

Rubber components operate under demanding conditions, as seals may flex thousands of times each day and gaskets are routinely exposed to heat, pressure, and aggressive chemicals. In addition, molded rubber parts often leave production coated with grease, mold release agents, and fine debris that adhere tightly to complex surface geometries. When the time comes to...

Can Ultrasonic Cleaners Effectively Remove Grease?

Grease has a way of showing up where it causes the most trouble. It hides inside blind holes, clings to threads, and settles into surface textures that brushes and sprays struggle to reach. Over time, it interferes with assembly, affects coating adhesion, and slows production. That reality explains why ultrasonic cleaning continues to attract attention...

Ultrasonic Cleaners For Military Optics: Four Key Benefits

Maintaining the high performance of military optics requires precise, efficient cleaning methods. The intricate components and sensitive lenses used in optics demand careful attention to support their longevity and functionality. An ultrasonic cleaner for military optics is a highly effective cleaning solution that does not compromise the integrity of these critical components. In this article,...

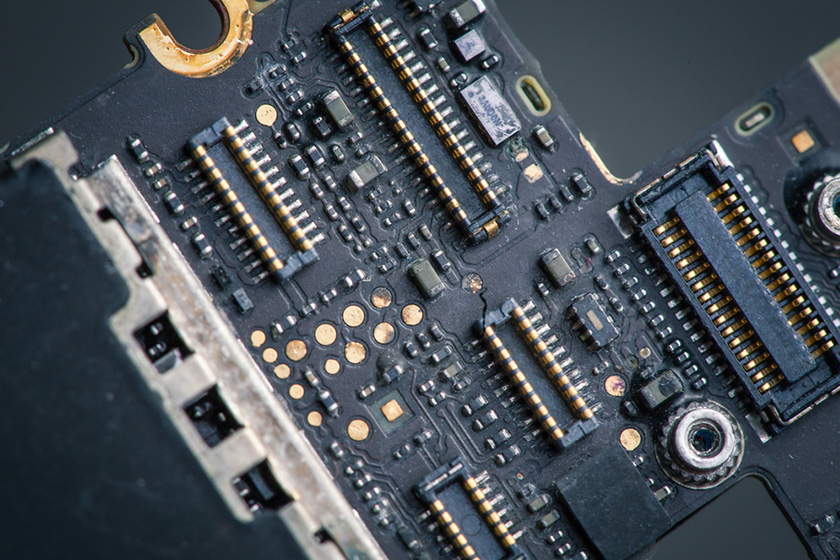

Is It Safe To Clean A Circuit Board With Water? Six Key Considerations

Circuit boards are the heart of nearly every modern electronic device. Keeping it clean supports the longevity and optimal performance of electronic devices. But can you clean a circuit board with water? While it might seem like a simple solution, there are several factors to consider before using water to clean delicate electronic components. In...

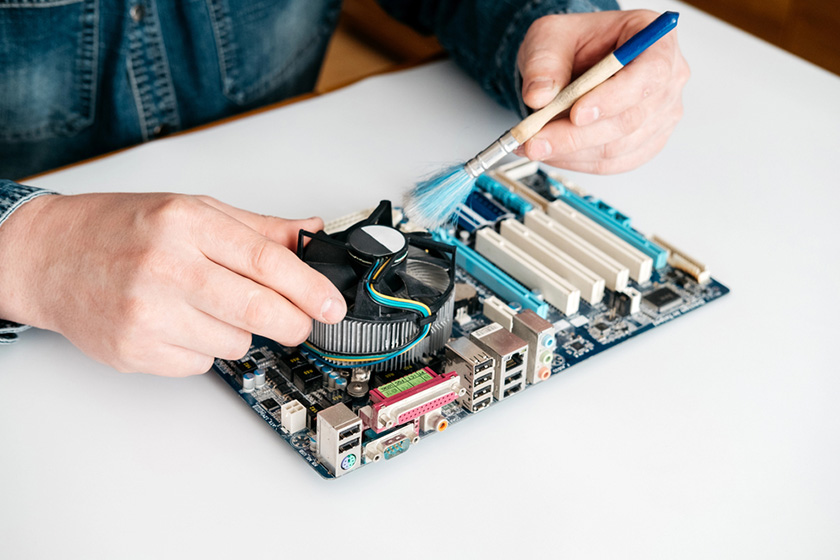

How To Optimize Circuit Board Cleaning Equipment For Maximum Efficiency

Cleaning circuit boards is an important part of maintaining the performance and longevity of electronic devices. For manufacturers, technicians, and engineers, achieving the highest level of efficiency in this process is vital. Many professionals wonder how to optimize circuit board cleaning equipment so as to enhance the speed, precision, and effectiveness of their cleaning procedures....

How To Effectively Protect PCB From Corrosion

Corrosion is a common yet harmful issue that affects Printed Circuit Boards (PCBs), leading to decreased performance or complete failure. Understanding how to protect PCB from corrosion can make all the difference in the longevity and efficiency of your electronics. In this article, we will explore effective methods for preventing corrosion, signs to watch for,...

Best Practices To Clean A Circuit Board Without Alcohol

Over time, the circuit boards in electronic devices can accumulate dirt, dust, grease, and other debris that could affect their performance. Isopropyl alcohol is commonly used in PCB cleaning, but there are times when alternatives might be preferable or necessary. In this article, we will explore how to clean a circuit board without alcohol and...

What Is The Best Industrial Parts Drying Method?

After any industrial cleaning, rinsing, or surface preparation process, the single factor that determines a component's fitness for the next stage is its dryness. Even microscopic traces of moisture can promote flash corrosion, compromise adhesion for subsequent coatings, and introduce minute residue that destabilizes sensitive assemblies. When parts exit the wash stage of a typical...

How Much Does Contract Manufacturing Cost?

When businesses look to scale production without investing in new facilities, they often turn to contract manufacturing. How much does contract manufacturing cost? The price can vary significantly depending on various factors, including the complexity of the product, order volume, materials, and more. Understanding these underlying pricing factors can help set realistic expectations and optimize...