Industrial dryers are used in manufacturing, processing, and research. They are designed to remove moisture from materials, improving quality, preserving products, and preparing materials for further processing. In this article, we’ll explore the different types of industrial dryers and how they work, highlighting their applications across various industries. Let’s break down each dryer type and...

Author: admin

How To Pick The Best Ultrasonic Cleaner Frequency For Your Needs

Ultrasonic cleaning has become the preferred method for precision cleaning across various industries. The effectiveness of ultrasonic cleaning largely depends on the ultrasonic cleaner frequency chosen for the application. Selecting the correct frequency can make a significant difference in cleaning efficiency, time, and the longevity of the components being cleaned. In this article, we’ll help...

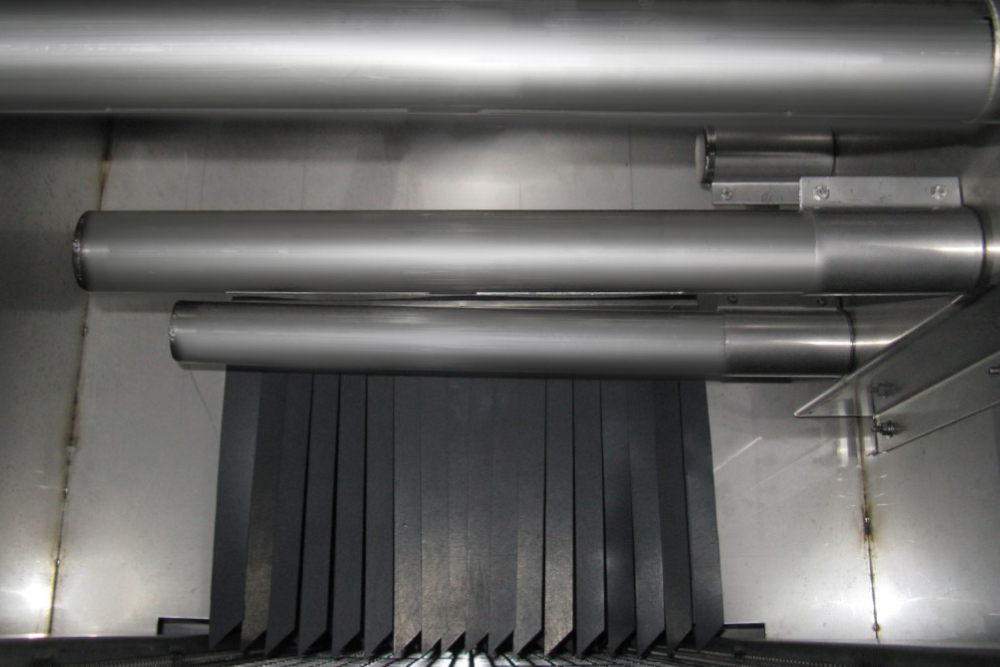

How To Improve Industrial Dryer Performance

In manufacturing, every minute counts, and improving industrial dryer performance can make a world of difference in efficiency and cost savings. Whether you're trying to speed up drying times or achieve more consistent results, optimizing your dryer can significantly boost productivity. But how do you know where to start? The key lies in understanding the...

How To Clean Inconel: Industrial-Grade Techniques For Tough Alloys

Inconel, a high-performance metal alloy, is known for its exceptional resistance to heat, oxidation, and corrosion, making it indispensable in industries like aerospace, chemical processing, and energy. Cleaning Inconel requires special techniques, as improper cleaning can lead to surface damage or diminished performance. In this article, we’ll discuss how to clean Inconel effectively using industrial-grade...

How To Clean Beryllium Safely And Effectively

Handling Beryllium requires a precise, thoughtful approach to avoid hidden dangers that could put both your health and equipment at risk. This metal, often used in high-performance industries, poses serious health risks due to the dust and particles it emits during cleaning. Improper cleaning methods can lead to exposure, causing chronic respiratory issues. In this...

Contract Manufacturing Vs. Third-Party Manufacturing: Which One’s Right For You

The global manufacturing landscape has evolved into a complex network of specialized production partners, outsourced engineering teams, and multinational supply chains. In this ecosystem, choosing between contract manufacturing vs. third-party manufacturing can directly shape product quality, development control, timelines, and long-term scalability. For companies developing technical, engineered, or highly customized products, aligning with the right...

Will An Ultrasonic Cleaner Remove Glue Residue?

Glue residue has a way of overstaying its welcome. Labels peel away but leave behind sticky films, and protective tapes may come off while traces remain in corners and threads. Over time, these residues attract dirt, degrade coatings, and slow production when parts require rework. Manufacturers across a wide range of industries seek cleaning methods...

Vapor Degreasing For Circuit Boards: Understanding The Best Practices

Circuit boards carry tighter tolerances, smaller geometries, and higher performance expectations than ever before. Residues left behind during soldering, rework, or handling can quietly compromise reliability long after a product ships. Flux activators readily attract moisture, while ionic contamination promotes corrosion and dendritic growth, and protective coatings may fail to adhere as intended. Although these...

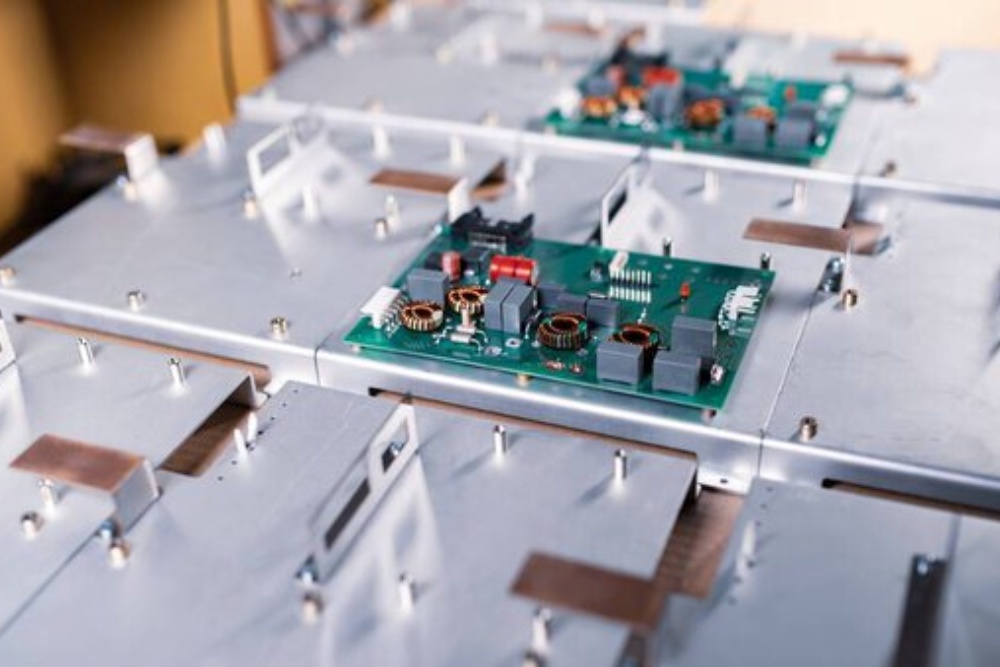

Enhancing Carrier Pallet Cleaning Systems For Electronics Manufacturing

In electronics manufacturing, the smallest variables often carry the greatest consequences. A faint layer of dust trapped in a pallet groove, or a static charge picked up during transport, can quietly undermine surface quality long before a defect is visible. Pallets and carriers move frequently among molding, assembly, inspection, and packaging. They’re among the most...

Does An Ultrasonic Cleaner Remove Carbon Buildup?

A fuel passage narrows, a mold releases less cleanly, or a precision component runs hotter than expected. What looks like a thin dark layer often hides a far more stubborn problem of carbon buildup. It’s an issue that has formed through repeated thermal cycles and chemical reactions rather than simple surface contamination. Once carbon takes...